Quality + colour + design = the perfect basket

Every one of our quality Bolga baskets starts out in the imagination of the weaver.

What size? What shape? What colours? What pattern?

The only thing that's absolutely not a variable is quality. For us - and for you - that's a given.

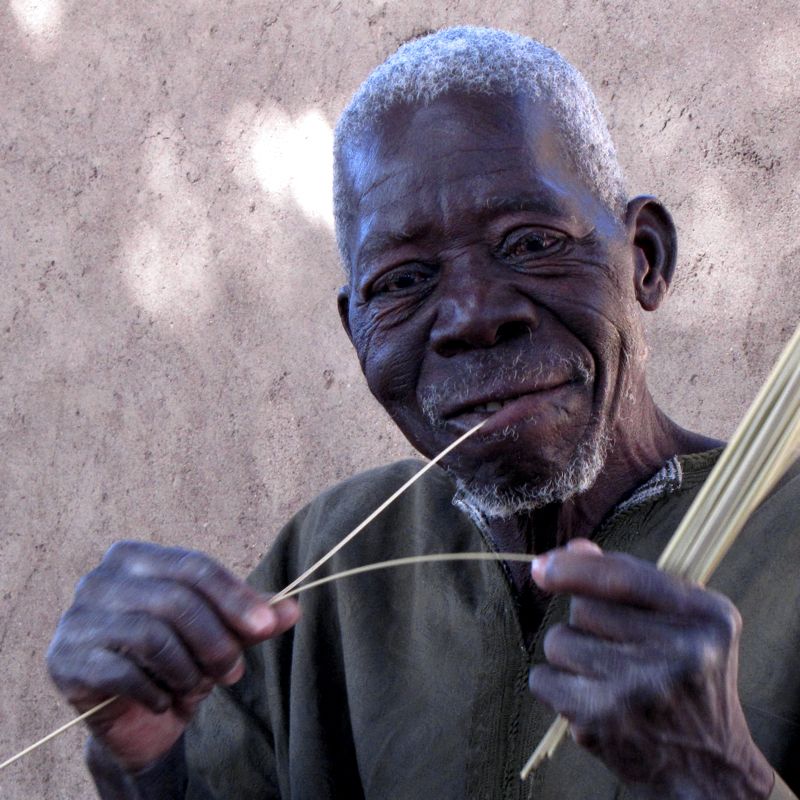

Preparing and splitting the straw

Our baskets are made from hollow stalks of dried elephant grass.

First, the weaver splits the grass or straw into two long strands.

Next, by rolling these strands across an old flip flop strapped to a thigh, the weaver twists these two strands together. This makes the grass stronger and more pliable for weaving.

Dyeing the straw

Next, specialists dye the prepared elephant grass in big vats of industrial quality chemical dyes.

To our knowledge, nobody around Bolga uses any sort of natural or vegatable dyes.

Finally, after selecting a range of colours, the weaving begins.

Weaving the basket

Every basket starts in the middle and the start is critical. If you start wonky, you'll finish wonky.

All of our baskets - regardless of shape - are woven as a single, integral shape. There are no sewn seams to wear out and fail. That's why our baskets are so strong and also why you can reshape them over and over again.

The precise weaving pattern, like the colours, is up to the weaver.

How long does it take to weave a basket?

That depends on the shape, size and complexity of the basket; also on the skill and experience of the weaver.

A 16-inch round market basket contains around 25,000 'knots' - that's the interface between warp and weft straws. Total time: 2-4 days - not including preparing and dyeing the straw and not including the rim or handle.

A large pot basket takes at least 3-4 days. Really big and difficult baskets like Jemima 10 Cows take even longer.

Attaching the rim and handle

Weaving and attaching the rim and handle is a special skill. Some weavers can do it, but many pass their baskets on to more experienced weavers for this step. Why? Because a wonky handle will ruin an otherwise perfect basket.

Covering the handle with leather

Not all baskets have leather-bound handles. Ours do because leather makes them stronger, more comfortable to carry and even more beautiful.

When we're in Bolga, after we've chosen our baskets and before we pack them for shipping home, the Leather Boys work feverishly - sometimes through the night - stitching on our leather handles.

Making money from weaving

The weaver makes baskets for one reason only: to earn money in a remote town where the cost of living is high and earning potential is low. The weaver has two choices.

Take it to the basket market in Bolga, where the big volume 'pile em high and sell em cheap' basket traders will drive the price down as far as they can. The weaver makes peanuts.

Or, weave for the Baba Tree Basket Company, where Greg MacCarthy will pay a much higher price - but only if the basket is absolutely perfect.

Splitting elephant grass: Bolgatanga, Ghana

Splitting elephant grass: Bolgatanga, Ghana

Dyeing elephant grass: Bolgatanga, Ghana

Dyeing elephant grass: Bolgatanga, Ghana

Weaving is a communal activity at the Baba Tree

Weaving is a communal activity at the Baba Tree

Okalah and the Leather Boys: Bolgatanga, Ghana

Okalah and the Leather Boys: Bolgatanga, Ghana